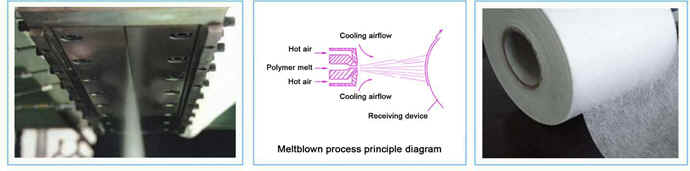

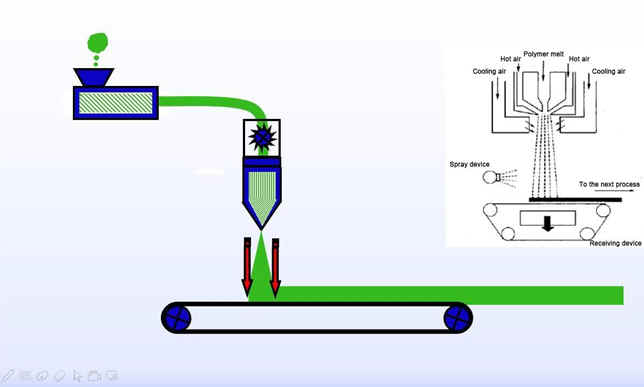

Melt-blown method is a method of direct polymer web forming. It is a method of extruding a polymer melt extruded by a screw extruder to extrude the melt stream by extreme high-speed and high-temperature air flow or other means. Very fine fibers are formed, and then gathered on a web forming drum or screen curtain to form a web. Finally, they are reinforced by self-adhesion to produce a meltblown fiber non-woven fabric.

|

| BlowMelt Nozzle |

The equipment has reasonable design, superior performance, uniform network formation and complete specifications. The width of meltblown non-woven equipment is 1.6 meters, 2.4 meters, 3.2 meters; the width, die, and nozzle of meltblown non-woven equipment are divided into domestic and foreign versions, which can be customized according to customer requirements. Version. The company has the right to self-import and export of meltblown non- woven equipment, and relying on high-end equipment and superb technology to provide one- stop services such as equipment installation, commissioning and training, enjoys a high reputation at home and abroad.

entire meltblown equipment consists of the host, heating system, lubrication

system, hydraulic system, meltblown spinneret, cooling system, electrical control system, high-pressure fan, network system, electrostatic electret, etc.

The main machine is mainly composed of feeding system, screw extruder, filtering device, metering pump, melt-blowing die assembly, receiving device and winding mechanism. When producing meltblown nonwoven materials such as polyester and polyamide, chip drying and pre-crystallization are also required.

| Process Flow: |

|

|

| Example Products: |

|